GTRI report: Made-in-India iPhones will sell cheaper despite tariffs in the US, Apple will remain profitable

According to the GTRI report, even if the US imposes a 25% tariff on iPhones made in India, their price will still be lower than iPhones made in the US. Manufacturing in India is a more profitable deal for Apple.

US President Donald Trump recently warned again to impose tariffs on iPhones from India and other nations imported into the US. Trump indicates that if Apple doesn't cease importing iPhones from foreign nations, then a tariff of 25 percent would be charged over iPhones in the US. In fact, Trump is stressing producing iPhones within the US so that the domestic economy within the US can be enhanced. Still, because it is costly to produce within the US, Apple at present is manufacturing most of its goods including iPhones in nations like China, India and Vietnam.

A new report has surfaced after Donald Trump's new statement on tariffs. The Global Trade Research Initiative (GTRI) report claims that even if the US imposes this tariff, the cost of manufacturing iPhones in India will still be much lower than manufacturing in the US. During the Doha Summit earlier this month, Trump revealed that he had asked Apple CEO Tim Cook to stop iPhone assembly expansion plans in India. Trump had said, "I don't want you to manufacture in India ... they can take care of themselves."

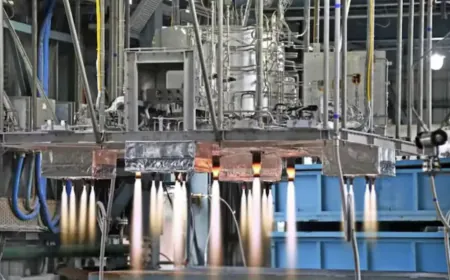

According to the GTRI report, the monthly salary of employees assembling iPhones in India is around $230, while in US states like California, this cost can reach around $2,900 per month. If Apple does this, the production cost will increase by 13 times.

Apple spends an average of $30 per unit to assemble iPhones in India, while the same process in the US can cost $390. Apart from this, Apple also gets additional benefits under the Production Linked Incentive (PLI) scheme of the Government of India.

If Apple assembles iPhones in the US, it will get a profit of only $60 instead of a profit of $450 per unit, or the company will have to increase prices significantly due to rising costs.

The cost of an iPhone is around $1,000, with dozens of countries contributing to this. Apple gets the highest profit of about $450 per unit. US component makers such as Qualcomm and Broadcom get around $80. Taiwan gets $150 for chip manufacturing, South Korea $90 for OLED screens and memory chips, and Japan $85 for camera lenses. Other countries such as Germany, Vietnam, and Malaysia together earn only $45.

Both India and China get around $30 per unit for assembly, which is less than 3% of the iPhone's retail price. iPhone assembly in India has created around 60,000 jobs, while in China the figure is around 3 lakh.

Also Read: Two new phones of Oppo Reno series launched, 50MP selfie camera; Know the price

For Latest News update Subscribe to Sangri Today's Broadcast channels on Google News | Telegram | WhatsApp

.jpeg)